Design. Build. Fly.

Design. Build. Fly.

Design. Build. Fly (DBF) is an aviation-based engineering design team. DBF focuses on the creation of a unmanned, electric powered, radio controlled aircraft that is designed to best fit a given mission profile. Each year, a new mission is given which is designed to mimic a real world engineering problem.

Projects

Projects

2024 - 25 Project Year

Competition Summary:

This year the competition entails unique design challenges such as creating a smaller glider inside of the main body of the plane. The design team sent out an application to the AIAA hosted competition and has been accepted into the competition. The plane has been called Precision Unmanned Model Aircraft (PUMA) and is slated to have a test flight on March 29th 2025.

Design Solution:

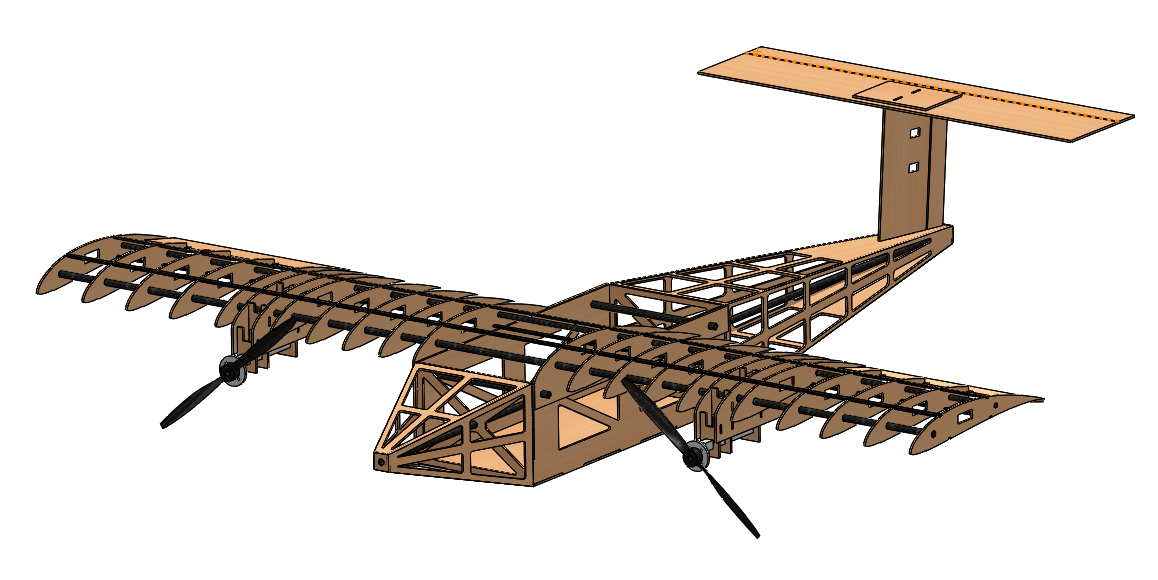

Using solidworks and adobe illustrator, the design team created a in depth 3d model. The model features an impressive six-foot wingspan. There are two fuel tanks (seen in green) which will house simulated fuel in accordance with the competition rules. The plane will also have a deployable glider.

The 3d model of PUMA

The cover image for the report sent to AIAA

2023 - 24 Project year

Competition Summary:

Design Solution:

Using solidworks and adobe illustrator, the design team created a in depth 3d model.

Competition Results:

2019 - 20 Project year

The team build, tested, and landed their first prototype

Working on motor control while calculating an efficient banner and passenger ratio.

This year, one of the requirements is to have a large banner pulled behind the plane (Nebraska banner below). The ratio had to be 5:1 (length to width) and the larger the better!

successful test flight

2019-20 Competition Summary:

The 2020 competition is based on a “banner towing bush plane.” The plane is designed to carry as many simulated passengers and their luggage as possible. Additionally, the plane must externally carry, and deploy in flight, a towable banner, which then has to be released before landing. A larger banner, more passengers, and a quicker aircraft results in a higher score. All of these features are restricted to a maximum wingspan of 5 feet. The competition was scheduled to be held April 16-19 in Wichita, Kansas but was cancelled after concerns of COVID-19. Therefore, teams were only scored based on the reports they submitted, and by this criteria, the UNL DBF team scored 22nd place out of 101 teams.

Although unable to attend the actual competition the team was still able to enjoy painting the passengers and their yearly test flights out at the air strip. Through and through, the competition was a success and the returning members of DBF is excited and ready to take on the next design!

MEMBERS

With a new annual mission, students are challenged to propose and test new ideas, while maintaining knowledge of basic engineering principles. DBF involves an extensive design process that gives students opportunities to learn about these engineering principles and explore the steps of an engineer to complete a set goal. Within DBF, students will work with a team of other aspiring students to successfully create an aircraft and compete with other schools from around the world.

2020-21 TEAM LEADS:

Organization: Kevin Zhao

Design: Thomas Curry

Aerodynamics: Samuel Schneider

Propulsion: Herve Mwunguzi

Manufacturing: Thomas Schoenstein

Secretary/eSAB Representative: Louis Sully

Treasurer: Ryan Karl